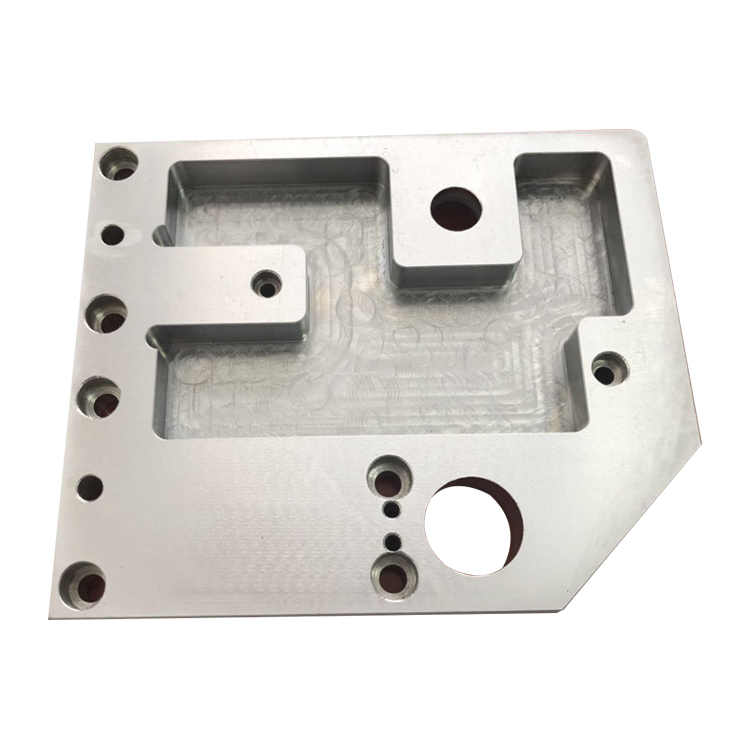

CNC Machining of Automobile Mould Parts

CNC machining plays a vital role in the production of automobile mold parts, ensuring precision, efficiency, and high-quality results. The process involves the use of computer-controlled machines to remove material from a solid block or billet, transforming it into the desired shape and dimensions.A......

Send Inquiry

Product Description

CNC machining plays a vital role in the production of automobile mold parts, ensuring precision, efficiency, and high-quality results. The process involves the use of computer-controlled machines to remove material from a solid block or billet, transforming it into the desired shape and dimensions.

Automobile mold parts require exceptional accuracy and surface finish to ensure proper fit, functionality, and durability. CNC machining provides the necessary capabilities to achieve these requirements consistently. Here are the key aspects of CNC machining in the production of automobile mold parts:

1. Design and Programming: Skilled technicians or engineers create a detailed CAD (computer-aided design) model of the mold part. This model is then converted into a CNC program that guides the machining process.

2. Material Selection: High-quality materials, such as steel or aluminum, are carefully chosen based on the specific requirements of the mold part, considering factors like strength, heat resistance, and dimensional stability.

3. CNC Machining Processes: Various CNC machining processes are employed to shape and refine the automobile mold parts. These processes may include milling, turning, drilling, grinding, and EDM (Electrical Discharge Machining) to achieve the desired geometry and surface finish.

4. Precision and Accuracy: CNC machines are capable of achieving incredibly tight tolerances, ensuring that the mold parts adhere to the required specifications. This precision guarantees proper fit and alignment with other components in the mold assembly.

5. Surface Finish and Texture: CNC machining allows for the creation of smooth and uniform surface finishes on the mold parts. This is particularly crucial as it helps prevent defects and imperfections in the final products that would be molded using these parts.

6. Iterative Refinement: CNC machining allows for iterative refinement of the mold parts based on testing, analysis, and quality control. Any necessary adjustments can be made to the CAD model and translated into updated CNC programs, ensuring continuous improvement in the manufacturing process.

By leveraging CNC machining for the production of automobile mold parts, manufacturers benefit from enhanced efficiency, accuracy, and repeatability. The technology enables faster turnaround times, reduces human error, and ultimately contributes to the overall quality and performance of the molded automobile components.